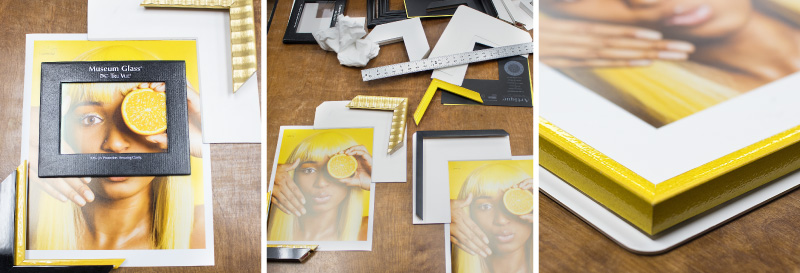

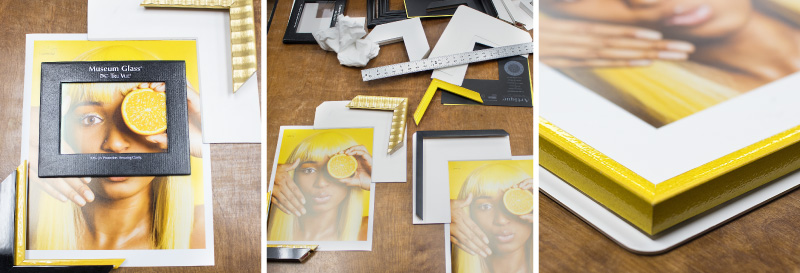

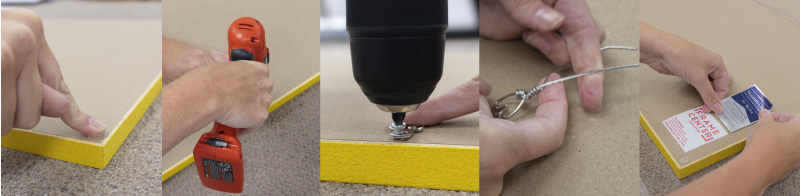

Framing Process

THE FRAMING PROCESS

Custom framing can be a relatively straight forward process or a highly specialized, complex undertaking. Depending on the unique specifications of your framing needs, our in-house consultants will help you identify the process that’s right for your project. You can be certain that we will walk you through the process – from start to finish – ensuring that your expectations are met, and you know exactly what your finished project will look like and when it will be completed.